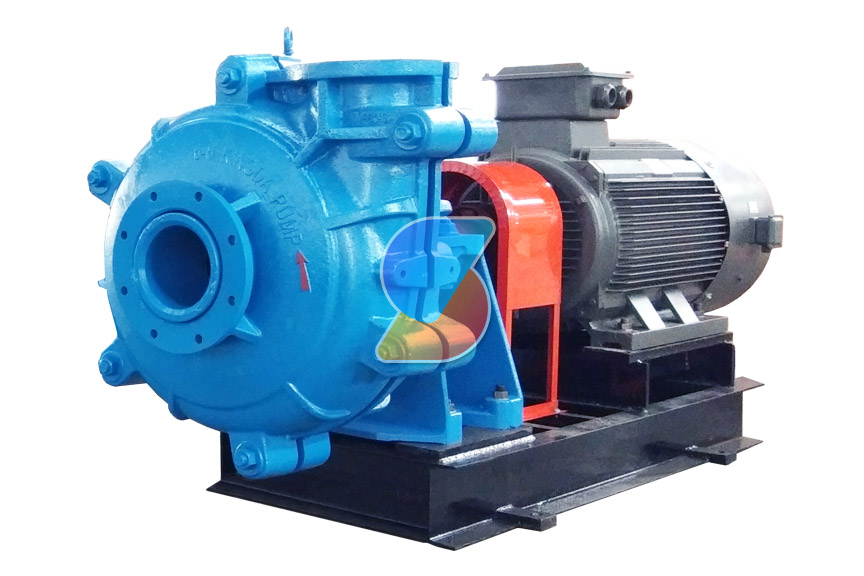

Rubber Slurry Pump Parts are an unavoidable cost associated with operating centrifugal slurry pumps, the primary slurry pump parts included impeller, volute, frame plate liner insert, throatbush and bearing assembly provides replacement parts for Warman pump spare parts and stock a range of slurry pump wetted end parts which have been developed for abrasive applications in mines, quarries, sand and gravel etc.

The Main Parts for Metal and Rubber Slurry Pump Parts:

•

Bearing assembly - A large diameter shaft with short overhang minimizes

deflection and contributes to long bearing life. Only four through

bolts are required to hold the cartridge type housing in the frame.

• Liners - Easily replaceable liners are bolted, not glued, to the

casing for positive attachment and ease of maintenance. Hard metal

liners are completely interchangeable with pressure molded elastomers.

Elastomer seal rings back all liner joints.

• Casing - Casing halves of cast or ductile iron with external

reinforcing ribs provide high operating pressure capabilities and an

extra measure of safety.

• Impeller - front and rear shrouds have pump out vanes that reduce

recirculation and seal contamination. Hard metal and molded elastomer

impellers are complete interchangeable. Cast in impeller threads require

no inserts or nuts. High efficiency and high head designs are also

available.

• Throatbush - Wear is reduced and maintenance simplified by the use of

tapered mating faces to allow positive accurate alignment during

assembly and simple removal.

Next: Last

+086-13363833280

+086-13363833280 1245738092@qq.com

1245738092@qq.com